Fancy Colored Diamond Recut

Recut is a process of re-polishing polished diamonds.

In fancy colored diamonds, the value of the diamond is determined by 3 main parameters: color, clarity and weight. For that reason, any change in one or more of these parameters may lead to a significant change in the value of the diamond.

The purpose of the re-polishing process is to improve the grades in the GIA certificate in various parameters, such as: color, clarity, symmetry, polish etc., in order to raise the value of the diamond (upgrade).

Performing a recut of a polished diamond requires a long-time expert in this special field of work. The main reason for that is that alongside the probability of performing a successful recut, there is also the risk of causing severe damage, which, of course, may lead to a major loss of money.

Over the years, we’ve created a working method that is based on our broad experience and advanced technology.

This method allows us to figure the exact potential of the diamond, find the exact flaw and fix it topically, avoiding unnecessary weight loss.

In the following section, we will walk you through the recut process, in the purpose of improving the color grade in the GIA certificate as we perform it in our company

First, we need to look at the parameters affecting the color appearance in fancy colored diamonds:

1. The rough

in the crystallization process of a fancy colored diamond, as opposed to colorless diamonds, there is also the element of the various materials and minerals in the soil. Those elements cause changes in the anatomical structure of the diamond, leading to various color changes, for example – blue to gray is usually caused by boron, yellow is mainly caused by nitrogen etc.

However, those colors come in all different undertones and levels of intensity. To demonstrate, even diamonds with similar GIA certificates may look evidently different from one another. The body color of a polished diamond is examined in a table-down position in a color paper, in a neutral environment, with attention to the following:

- Colorless environment – as neutral as possible

- Even temperature – away from extreme cold or heat

- Constant lighting

- White color paper only

2. The diamond’s structure

various structural parameters affect the color appearance of the diamond.

After we went through the factors causing the differences in the diamond’s color appearance, we will walk you through the recutting process the way it is being performed in our company step by step.

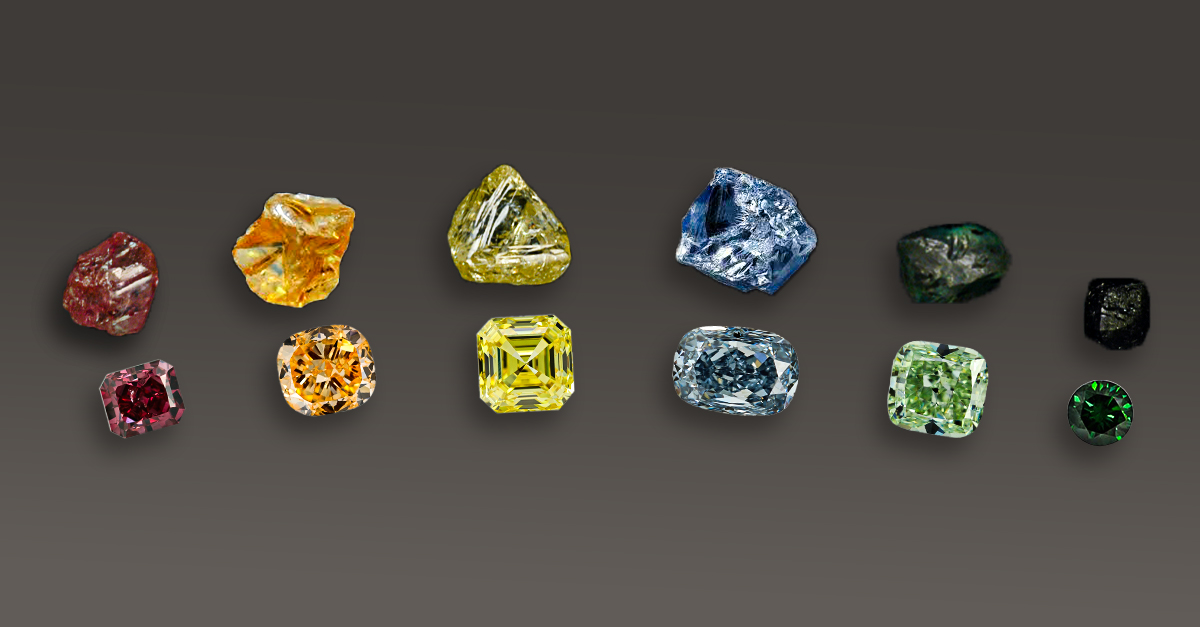

This is an example of different colors in different shapes

As the diamond reaches our examination table, we perform several steps in order to decide whether we should recut the diamond as follow:

1. Material probability assessment

At this stage, the initial color of the diamond is categorized to acknowledge where the color border stands in comparison to its certificate grade. To assess these borders accurately, we developed a tried-and-true work method that is found to be efficient and reliable through successful experience over the years.

Furthermore, we independently developed a variety of technologies that support our decision-making process.

2. Making recut plans, considering structure and weight limitations

At this stage, the entire team gathers to discuss the possible options of improving the diamond color. Opting for the ideal solution, we figure ways to improve the color grade without damaging its other main parameters (clarity, weight category…). We also bring into consideration the structural limitations of the diamond.

*It should be noted that an ideal solution is not always to be found. The more severe the limitations are, the fewer options are available.

3. The financial aspect

After the weight loss estimation, we make a value assessment of the diamond in its current condition, followed by a value assessment of the end product. The result must reflect economic viability.

4. Risk - reward evaluation

After analyzing all factors listed above, we assess the probability of success versus the chances to fail. Having the right conditions, we make the decision to perform the recut.

5. Executing the recut plan

The diamond is being re-polished in our factory according to the plan we made. After every step of the re-polish process, the team gathers to examine the next steps, as each step affects the following steps to come.

*In re-polish process, precision is a key element.

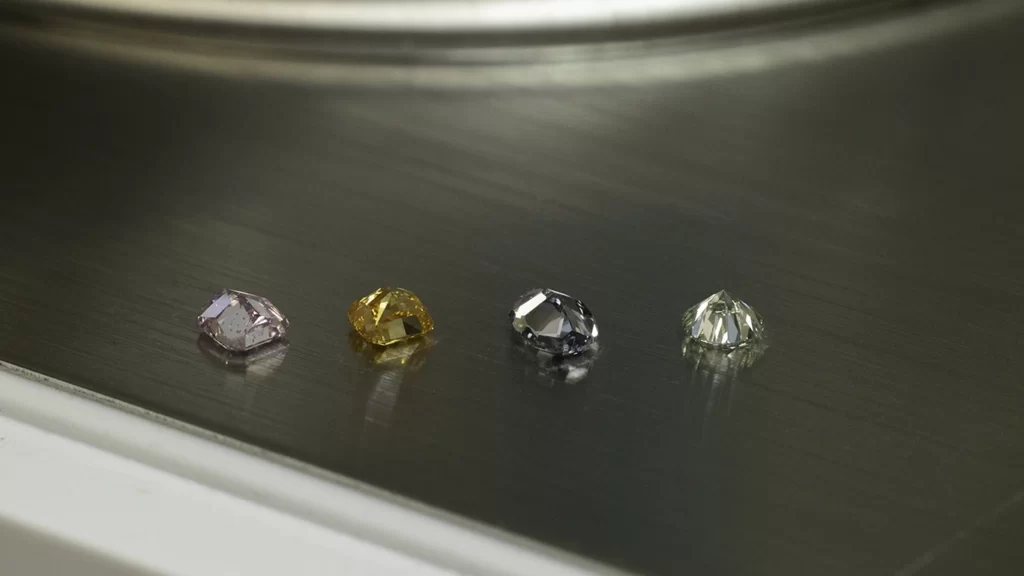

6. Examination of the diamond prior to sending to GIA

The team reconvenes to decide whether the outcome is believed to successfully improve the grade in the GIA certificate. If so, we send the diamond for re-certification.

7. GIA certificate

The diamond is being sent to the GIA laboratories to receive the new grades.

In the end of the process, the diamond is returned to its owner with the new certificate, stating the new and improved grade.

Find more about our diamond recutting process.

If you find this might be helpful for your company, and you would like to examine whether your border-line fancy colored diamond can be improved and upgraded, we would love to be at your service!